Steel is the backbone of modern construction, right from residential towers to infrastructure projects. But today, a new question is entering boardrooms and project sites alike: Should you stick to traditional steel or shift to green steel? Let’s find out.

What Is Traditional Steel?

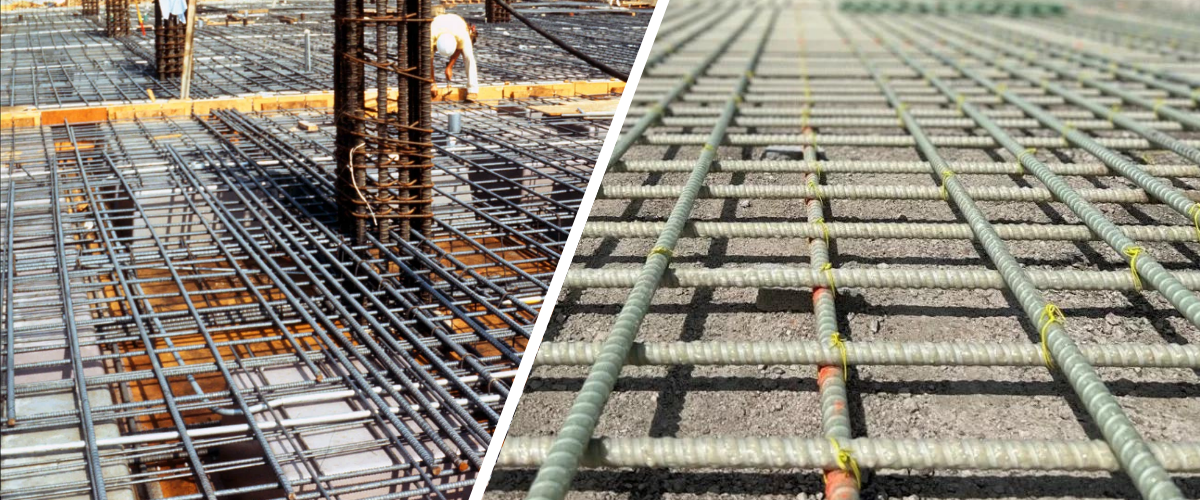

Traditional steel is produced using blast furnaces, where iron ore is heated with coke (derived from coal). This process has powered industrial growth for over a century, but it comes at a cost. Steel is associated with high carbon emissions. In fact, it accounts for ~7–9% of global CO₂ emissions. It is also coal-dependent, with heavy reliance on fossil fuels. Despite this, traditional steel remains the default choice for most projects due to its reliability, standardization, and accessibility. Green Steel, however, is flipping the industry scenario.

What Is Green Steel?

Produced using low-carbon or carbon-free methods and highly sustainable materials, such as glass or basalt fibers embedded in polymer resins, eliminating the need for iron ore processing altogether. The goal? Dramatically cut emissions without compromising strength or durability.

Green steel successfully reduces up to 90–95% lower CO₂ emissions, uses renewable energy or green hydrogen, offers the same structural performance as traditional steel, and is becoming a more acceptable alternative to steel.

What Does This Mean for Construction Projects?

Choose Traditional Steel if:

- You’re working with legacy specifications that haven’t yet approved composite alternatives

- The project is short-term or temporary in nature

- Exposure to corrosion, chemicals, or moisture is minimal

Choose Green Steel if:

- You want lower lifetime costs due to minimal maintenance and longer service life

- High tensile strength and superior corrosion resistance are critical to structural performance

- The project is in coastal, industrial, or high-moisture environments

- You’re aiming for lighter structures, easier handling, and faster installation

- Sustainability, ESG, LEED, or net-zero goals matter without inflating the budget

Many governments and global frameworks, including the Paris Agreement, are accelerating the shift toward low-carbon construction. As a result, green materials like composite rebars are increasingly becoming a practical default and not just a premium alternative, offering durability, strength, and cost efficiency alongside environmental responsibility.

Is Green Steel the Future of Construction?

Yes, green steel is best suited for:

- Premium commercial projects

- Forward-looking developers

- Pilot or showcase sustainable builds

- Marine construction and more

As technology scales and costs fall, green steel is expected to become mainstream much like solar energy did a decade ago.