Looking for the Best Glass Fiber Rebar Manufacturer in India

We manufacture and supply premiun quality Glass Fiber bar in India

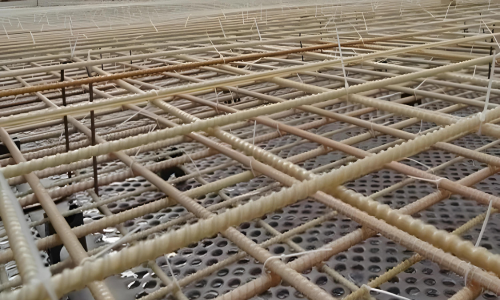

Glass Fiber rebar is designed to revolutionize reinforcement solutions by offering superior strength, durability, and corrosion resistance compared to traditional steel rebars. Made from high-quality glass fibers and a polymer resin matrix, these Dura Composites’ rebars are defined by their lightweight, non-magnetic, and non-conductive qualities. They are ideal for a wide range of construction applications, such as marine structures, bridges, tunnels, or highways.

GFRP bars are used as an alternative to traditional steel reinforcement bars (rebar) in concrete structures. They offer excellent corrosion resistance, as they are not susceptible to rust or chemical degradation. GFRP bars are lightweight approximately 75% lighter than TMT bars, making them easier to handle and transport, and they have a high strength-to-weight ratio, providing comparable or even superior structural performance to steel.

Dura Composite’s Glass Fiber Reinforced Polymer (GFRP) bent rebar is specifically engineered to provide high strength and durability while maintaining its designed shape. Unlike traditional steel reinforcement, which requires on-site bending, GFRP bent rebar is pre-formed to the required angles, ensuring precision and ease of installation. Its composite structure, consisting of glass fibers embedded in a polymer matrix, offers superior corrosion resistance and longevity compared to steel rebar.

Dura Composite GFRP Dowel Bars serve as load transfer mechanisms between joints within concrete slabs. They establish a mechanical linkage between slabs while accommodating horizontal expansion and contraction of the concrete itself. This feature reduces deflection at joints and minimizes stress on the slabs. Unlike steel dowel bars prone to corrosion, Dura Composite Glass Fibre Dowel Bars are corrosion-resistant, ensuring longevity and meeting shear capacity needs.

We manufacture and supply premiun quality Glass Fiber bar in India

Stays intact and rust-free even in the harshest environments, prolonging lifespan.

Reduces carbon footprint by using energy-efficient and longer life-cycle materials.

Promises quicker installation and efficiency by reducing labour & transportation costs.

Offers long-term savings by minimizing maintenance and replacement expenses.

Offers more strength and durability than steel, offering superior load-bearing capacity.

Ensures reliability by offering resilience against extreme pressure and heavy loads.

We manufacture and supply premiun quality Glass Fiber Bar in India

Dura Composites’s commitment to quality and prompt service has ensured seamless execution, making them our go-to choice for reliable solutions. Their ability to customize products to meet our project needs has contributed to our overall efficiency. We highly recommend their solutions for infrastructure projects requiring durability and precision.

Dura Composites’s products are incredibly easy to use and install. The fast installation process has helped us meet project deadlines efficiently, reducing both time and labour costs significantly. The durability and long-term performance of their products have also minimized maintenance efforts, ensuring hassle-free operations for our projects.

Dura Composites has been a game-changer for us. The cost savings and ease of use have made our residential construction more efficient, without compromising on quality. The lightweight yet robust materials have simplified our installation process while enhancing the structural integrity of our homes, making them a smart investment for long-term sustainability.

We used Dura Composites’s NEO-BENDS for NHAI drainage structures, and the design accuracy, fast installation, and major cost savings made a significant impact on our project! The durability of their products ensures long-term performance, reducing the need for frequent maintenance. We are confident that their innovative solutions will continue to add value to large-scale infrastructure projects.

Understand the key differences between steel rebar vs FRP rebar - compare strength, durability, corrosion resistance, cost, and sustainability to…

Explore how GFRP rebar is transforming sustainable construction with its corrosion resistance, lightweight strength, and eco-friendly benefits—ideal for modern, durable,…

Why GFRP rebar is the best choice for bridges, roads, and marine applications. With corrosion resistance, high strength, and sustainability,…

Glass Fiber Rebar is a high-strength, corrosion-resistant alternative to traditional steel reinforcement. It is made from fiberglass and polymer resin, ensuring durability and a long lifespan.

It offers transformative benefits like corrosion-resistance, light weight, high tensile strength, and non-conductive.

Our GFRP rebars meet ISO 9001:2015 standards and comply with GFRP BIS Code – IS 18256:2023, ensuring high performance and durability.

GFRP rebars last 2.5-3 times longer than steel due to their corrosion resistance, making them a superior long-term solution.

GFRP rebars are 25-30% more cost-effective than steel, saving cost and energy in labour, logistics, and maintenance.

Yes, we provide bulk discounts. Contact us for pricing details.

Orders can be placed via our website or by contacting our sales team. The minimum order quantity depends on the specifications.

Standard orders ship within 1-2 weeks; large or custom orders may vary.

Yes, we offer custom sizes and shapes to meet specific project needs.

Get in touch with us – we’re here to help and eager to hear from you!

Address

Plot no. D-2, MIDC Umred Nagpur MH 441203 IN.

+91 7038850006, +91 8669995445